WIP 04-11-2009

Posted: Sat Oct 01, 2022 12:00 am

I had finally decided after looking at reference photos that I was going to add the missing tread plate that the gun crew would've used as a platform. The tread plate can be clearly seen in both the MBI and Spielberger photos.

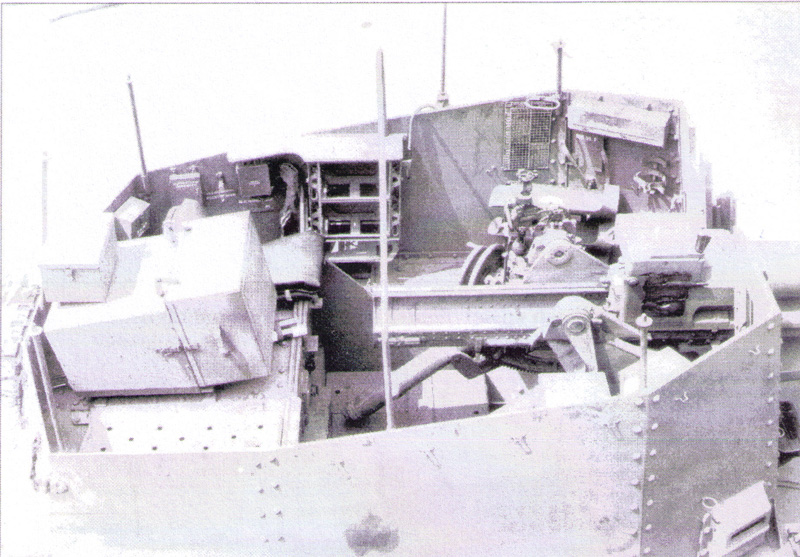

MBI:

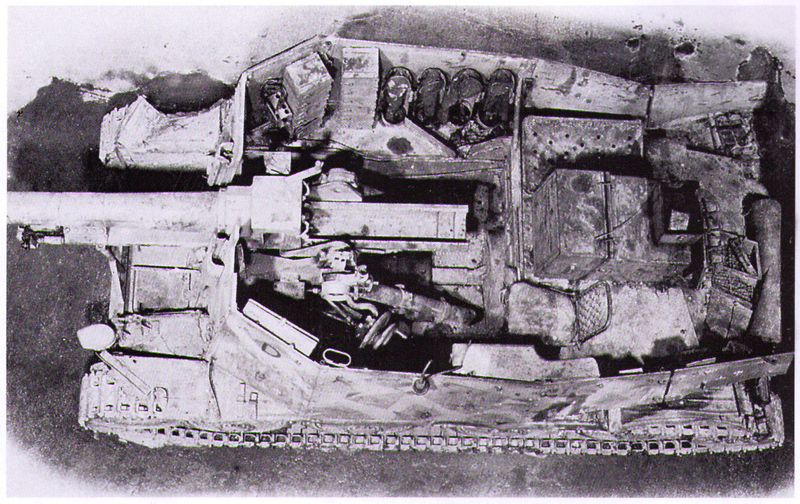

Spielberger:

In both photos you can see that the tread plate sits fairly high inside the lower hull, roughly flush with the curve over the bulkhead to the engine compartment on the MBI photo and about level with the drive shaft in the Speilberger photo. The Spielberger photo seems to have the simplified I-beam style of mount vs. the stepped style mount in the MBI photo, hence DML's option of mount types. I had used the stepped style so, in preparation for adding the tread plate, I did a dry fit of the gun mount and gun to see how things would line up using some poster blue tack to hold things in place.

I immediately noticed that something was wrong...the bases of the equilibrators were much lower than shown in either the

MBI or Spielberger photos. I compared the angles in the H mount vs. those in the M and it would appear that DML copied the angles from their earlier released M kit and didn't bother changing them for the H style mount which has a shallower angle configuration. This, to me, explains why there's no raised tread plate platform...if DML had included it, they would've had to change the angles on the equilibrators which would've required a totally new gun mount sprue. Instead, they stuck with the M style and omitted the plate. It also means that my plan to add the missing tread plate is now scrapped as it's impossible to change the angle on the equilibrators without completely replacing them due to the way they are integrated into the sides of the gun mount. That means I can't locate the plate at the correct height/level and throws everything off from an accuracy perspective and represents a substantial error on the interior IMHO.

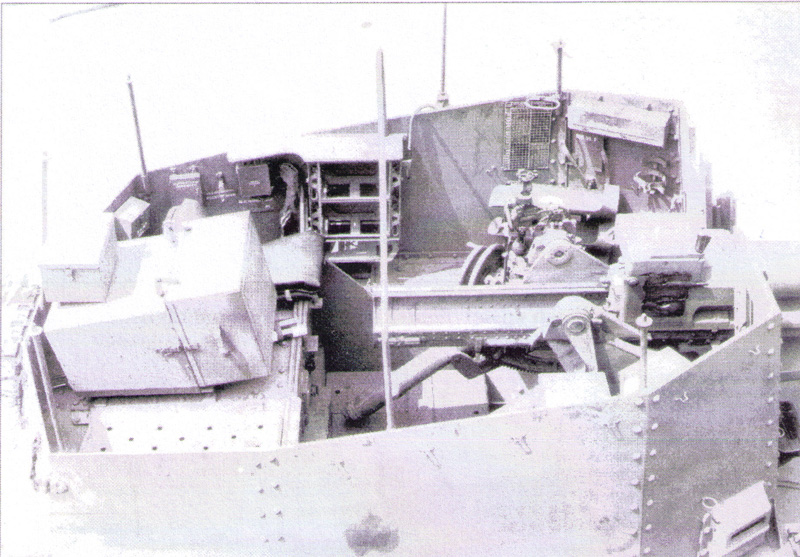

MBI:

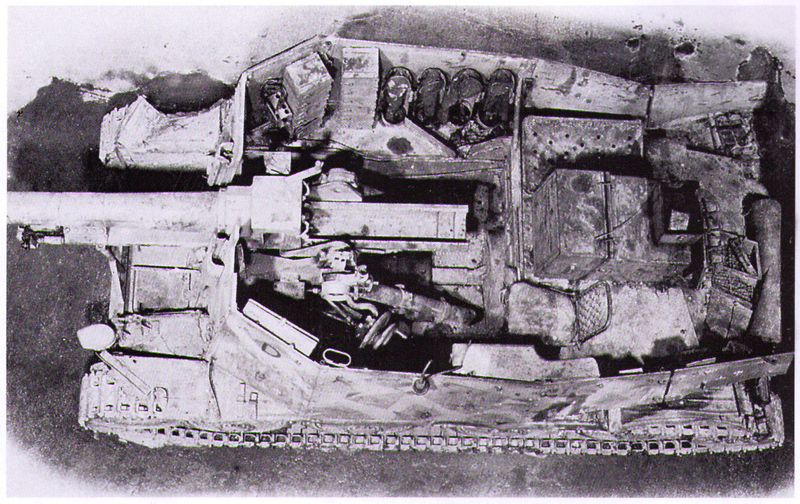

Spielberger:

In both photos you can see that the tread plate sits fairly high inside the lower hull, roughly flush with the curve over the bulkhead to the engine compartment on the MBI photo and about level with the drive shaft in the Speilberger photo. The Spielberger photo seems to have the simplified I-beam style of mount vs. the stepped style mount in the MBI photo, hence DML's option of mount types. I had used the stepped style so, in preparation for adding the tread plate, I did a dry fit of the gun mount and gun to see how things would line up using some poster blue tack to hold things in place.

I immediately noticed that something was wrong...the bases of the equilibrators were much lower than shown in either the

MBI or Spielberger photos. I compared the angles in the H mount vs. those in the M and it would appear that DML copied the angles from their earlier released M kit and didn't bother changing them for the H style mount which has a shallower angle configuration. This, to me, explains why there's no raised tread plate platform...if DML had included it, they would've had to change the angles on the equilibrators which would've required a totally new gun mount sprue. Instead, they stuck with the M style and omitted the plate. It also means that my plan to add the missing tread plate is now scrapped as it's impossible to change the angle on the equilibrators without completely replacing them due to the way they are integrated into the sides of the gun mount. That means I can't locate the plate at the correct height/level and throws everything off from an accuracy perspective and represents a substantial error on the interior IMHO.