WIP 02-20-2010

Posted: Sun Oct 02, 2022 7:08 pm

I had hoped to get to the painting stage today but two things tripped me up. The first was simply an underestimation of just how many parts I still needed to clean-up and add to the vehicle and the second was the realization that I didn't have all the paint supplies I needed on hand in sufficient quantities! So that means painting the exterior will be delayed until tomorrow but will still get done this weekend.

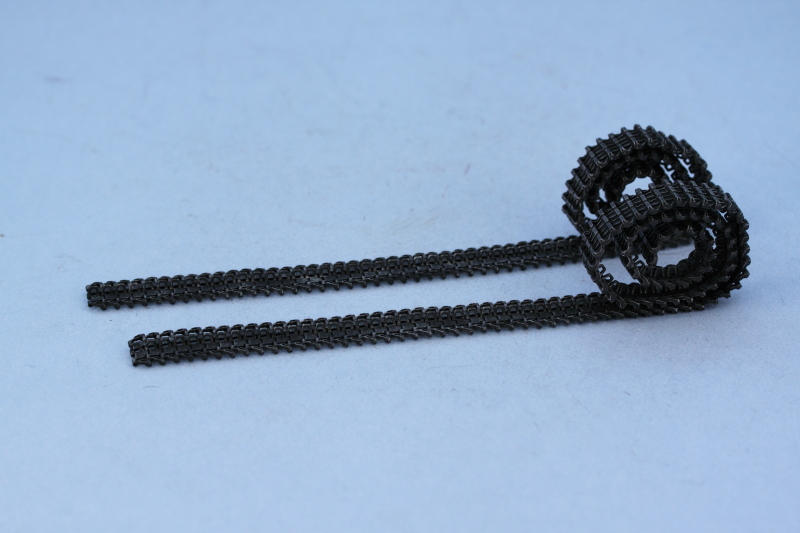

Speaking of all those parts to add, I went back through the different steps and conducted a survey to be sure I didn't miss anything. I test fit the kit-provided Magic links with the spare track holder on the hull nose and the links can slide in and out without problem so I went ahead and installed B3 from way back in Step 4. I also returned to Step 18 and added the lifting eyes, parts A4, to the rear exterior but left off the cleaning rods until after paint. All of the details in Step 21 were also installed, this covered the crew hatches, all the various lifting eyes on the hull glacis, and also the lifting eyes for the fighting compartment side panels. The mount holes for the A20 eyes was larger then the eye itself so a little but of putty was needed to fill those gaps.

After checking references, I realized that the three lower eyes called for in the instructions aren't seen on the actual vehicles...both the surviving examples in Kubinka/Aberdeen and numerous in-action photos don't show these as being there so I filled their small mount holes with putty and left them off.

I also completed the details in Step 22 which deals with the Bosch light and the jack. I assembled the jack but left it off for now to make it easier to paint that area of the fender and the hull. The instructions have an error here in that they call for the base of the Bosch light as part B40 but you actually need to use B39 or the actual Bosch light will install backwards. I drilled out the armored connection point on the glacis as well as the port on the Bosch base with a #72 finger drill and added the connecting wire conduit with 0.5mm diameter solder.

Step 24 was the last one I needed to work on and it deals with the gun travel lock. The instruction show this already assembled which makes things a bit tricky as there are no less than 8 parts that go into the assembly and some of them are very small. I used a #78 finger drill to carefully drill out the small pulley that is part M23 to allow me to add the missing tension cable that allowed the gun travel lock to be disengaged by the gunner from the relative safety of the fighting compartment vs. crawling out onto the glacis to do it. I drilled this hole while M23 was still on the sprue since it is a very tiny part. The travel lock was assembled and I was careful with the base parts to allow the lock to remain workable. This will help not only in the painting process but also provides options in the final display between the gun being secured or not.

The tension cable was added using waxed 0.008" diameter ship rigging thread which I glued in place on the glacis with small amounts of liquid glue and used regular glue to glue it into the base of the travel lock. The thread has sufficient flexibility that the lock can be moved freely without causing the thread to break free.

Now I'm off to the LHS to rectify my paint supply problem and tomorrow this one's got a date with the spray booth!

Speaking of all those parts to add, I went back through the different steps and conducted a survey to be sure I didn't miss anything. I test fit the kit-provided Magic links with the spare track holder on the hull nose and the links can slide in and out without problem so I went ahead and installed B3 from way back in Step 4. I also returned to Step 18 and added the lifting eyes, parts A4, to the rear exterior but left off the cleaning rods until after paint. All of the details in Step 21 were also installed, this covered the crew hatches, all the various lifting eyes on the hull glacis, and also the lifting eyes for the fighting compartment side panels. The mount holes for the A20 eyes was larger then the eye itself so a little but of putty was needed to fill those gaps.

After checking references, I realized that the three lower eyes called for in the instructions aren't seen on the actual vehicles...both the surviving examples in Kubinka/Aberdeen and numerous in-action photos don't show these as being there so I filled their small mount holes with putty and left them off.

I also completed the details in Step 22 which deals with the Bosch light and the jack. I assembled the jack but left it off for now to make it easier to paint that area of the fender and the hull. The instructions have an error here in that they call for the base of the Bosch light as part B40 but you actually need to use B39 or the actual Bosch light will install backwards. I drilled out the armored connection point on the glacis as well as the port on the Bosch base with a #72 finger drill and added the connecting wire conduit with 0.5mm diameter solder.

Step 24 was the last one I needed to work on and it deals with the gun travel lock. The instruction show this already assembled which makes things a bit tricky as there are no less than 8 parts that go into the assembly and some of them are very small. I used a #78 finger drill to carefully drill out the small pulley that is part M23 to allow me to add the missing tension cable that allowed the gun travel lock to be disengaged by the gunner from the relative safety of the fighting compartment vs. crawling out onto the glacis to do it. I drilled this hole while M23 was still on the sprue since it is a very tiny part. The travel lock was assembled and I was careful with the base parts to allow the lock to remain workable. This will help not only in the painting process but also provides options in the final display between the gun being secured or not.

The tension cable was added using waxed 0.008" diameter ship rigging thread which I glued in place on the glacis with small amounts of liquid glue and used regular glue to glue it into the base of the travel lock. The thread has sufficient flexibility that the lock can be moved freely without causing the thread to break free.

Now I'm off to the LHS to rectify my paint supply problem and tomorrow this one's got a date with the spray booth!