Lots of progress today on multiple fronts. Picking up from yesterday, I continued on with Step 2 and added the debris plow to the front of the car. This is a two-piece arrangement with each piece using 2 small tabs to attach to the lower hull on the rail car. I mounted the left side blade first using liquid glue to get it into the right position and then mounted the right side blade. The point where they meet, or rather are supposed to meet, at the front to form the angle of the wedge didn't line up perfectly but since the blades are a bit flexible, it was possible using regular glue and finger pressure to get them to match up. Once the regular glue had set, I came back with some liquid glue to fill the seam and then sand it down to finish the join.

The remaining part of Step 2 is the creation of the linkage gear for the front of the car and this is a complex assembly of 7 different parts. In the review I'd stated that these can be left workable with some care but after test fitting them together, the fit is sloppier than the linkage arrangement on the BR52 I'd built, which I'd assumed was the same on this kit. This combined with the complexity of the arrangement meant I held off until the front plate of the car was mounted before gluing and attaching.

Step 3 deals with the attachment of the front car plate and the necessary details. I attached the front plate first to the car hull to avoid damage to any details and the fit was generally ok, with some use of liquid glue and finger pressure at the edges necessary to get a good fit. Care is needed to make sure the plate stays flush with the top of the car sides as the deck plate will sit flush against this when it is installed. I was happy to discover that the bumpers do indeed have locater holes inside for the head-lamp bases, they look like ejector marks at first glance but are the exact diameter for the posts, so a few twists of the appropriate drill bit and they were opened up. These were attached without incident and the whole bumpers mounted to the plate. The linkage gear was assembled and installed, aligning it with the plow blades so it didn't snag. Last but not least, the side steps were installed. These are a delicate arrangement and the posts are smaller than the holes in the plate, so not only did they need bracing to get them to set in the right position while drying, they also required some putty to fill the gaps as well.

Step 4 is a simple step, it calls for the construction of the rear bumpers and the installation of the rear plate. The rear plate had the same issues as the front plate but otherwise installed cleanly.

Step 5 is a major step, it deals with the installation of the deck plate and the addition of the large wooden box to the deck rear. Test fits with the deck plate in previous steps prepared me for some slight gaps front and back and I'd deliberately not glued the sides to the wheel wells to insure it had some flexibility for this step. I used regular glue front and back and at the corners and several large rubber bands along with liquid glue along the sides.

While drying, I assembled the wooden box, creating the square out of the sides and sloped front and back first to get them aligned and then added the top. The molding has very nice wood grain and alternates the boards so that the pattern isn't the same over the different planks.

The rubber bands then came off the car. The sets set up well but the front and back plates needed more attention. I used additional liquid glue and finger pressure in select spots to get them closed up. Only a couple small spots needed some putty help.

That completed the car construction, so the next step started in on the turret interior. First up was construction of the two-piece gun and breech. I used regular glue here and then sanded down the seam with a sanding twig.

The coaxial turret MG34 was also constructed out of its three parts and the muzzle drilled out with a pin vise.

The gun mount and recoil guards were constructed and attached. The recoil shield has a very large ejector mark on the surface facing the breech, so if the right side turret hatches are left open, it will be very visible. Since I'm not going to have the interior displayed, I didn't fill this or any of the other many sink marks present. The left side of the gun mount includes a gear that keys to the elevation teeth on the recoil guard, which means that the gun will not elevate easily once installed, so before installing into the turret it would be a good idea to make sure it's set at the angle you want.

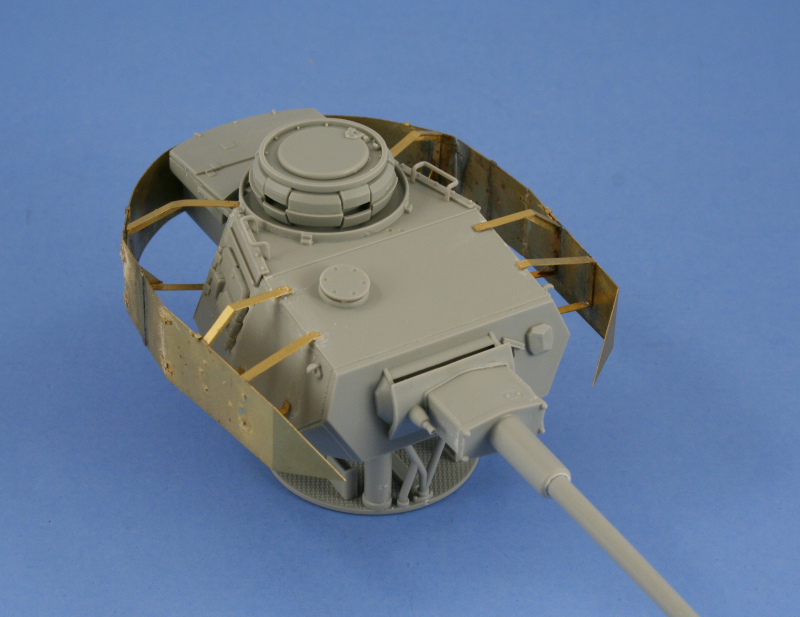

Next up came the construction of the exterior armored cover for the recoil housing. This is a four part assembly and the two square parts of the housing, B33 and B32, fit together really well. The same was not true of part B34, the gun barrel sleeve. This didn't align at all and I was able to get the top to align but all the other three surfaces required putty and sanding to get them to match properly. This was slid down over the barrel and glued into place and another problem revealed itself, the diameter of the sleeve is too large relative to the diameter of the barrel. Whether the gun barrel is too small or the sleeve too large is up for debate, but there's clearly too much room there for one reason or another. Last but not least, I assembled the two-part muzzle brake and cleaned up the exterior seam with a sanding twig but couldn't get at the interior surfaces very well for the obvious reasons. The opening on the front of the brake also wasn't molded circular between the two halves, requiring some attention with a round needle file to correct.

Next up will come the turret details and interior.