Today was a very productive day and at every step along the way I have to keep reminding myself it's all about the details! This in turn means that I have to give a lot of thought to the how and when things are dealt with...and that means things often happen in bursts.

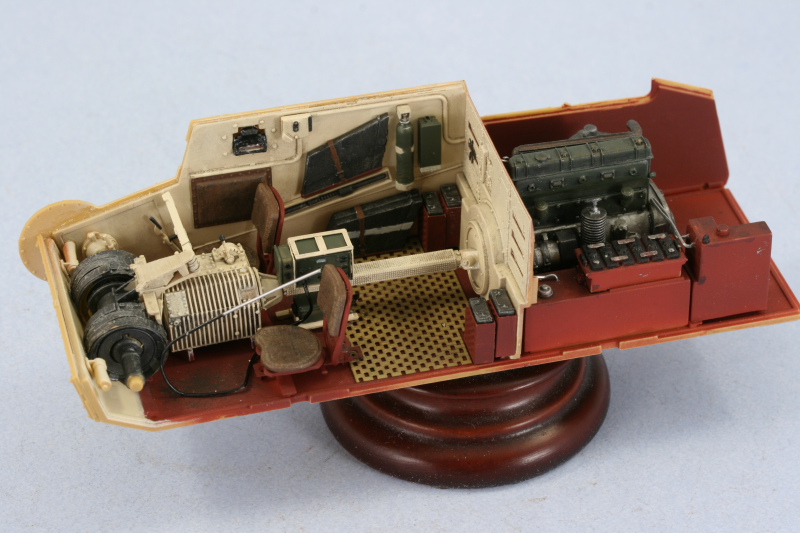

The first burst was to add some detail to the engine area. I installed the engine permanently into position using the firewall as a prop to insure the engine sat level while the glue dried. After it had set, I used a #72 finger drill and drilled some shallow holes in the fuel tanks to support some fuel lines. The diagrams in PT 13 show that the fuel lines fed to the pump panel on the firewall so I used some 1mm diameter solder for the lines and glued the ends into the drilled holes with CA gel and then carefully bent them into the desired shape. The will be glued into the panel on the firewall once it's installed to insure everything connects up. The diagram also showed two lines running from the auxiliary reserve fuel tank on the left side towards the engine so those were added as well. The engine still needs the exhaust pipe running out to the exterior, I will add that once the radiator is installed.

Next up was the hull glacis plate. I had decided not to open up the hatch here to display the brake housing due to the way the hatch opens up, so it was installed closed. I added the clutch pedal and instrument panel and other small details. Test fits showed that I needed to sand/trim down a bit in the center for proper clearance on the steering lever column. Not sure if this is a kit issue or one I introduced in assembling the column, but either way it had to be dealt with to avoid problems with the hull sides fitting correctly.

Continuing on with the hull front, the superstructure front plate received various details in the form of the radio opertor's visor and armored glass block, the driver's periscope and housing, and the communication light panel with the commander. Due to the curved plate, there was a large ejector mark dead center that required some very careful putty and sanding work to deal with. The curve also meant that the position of the light box ended up slightly different that what is displayed in the Tristar Interior Set instructions. Those instructions assume the front plate is straight as seen on the E/F and G variants so I had to improvise a bit to get it in the right spot and still clear the hull side panel. The improvisation involved trimming down the molded-on wire conduit there by a couple of mm to accommodate the bent plate design. I used poster blue-tack putty to mask off the portions of the clear parts that I needed to preserve clear and that was it for this part.

Speaking of the hull sides, it was now time to give them some attention as well. I installed the axle hubs into the brake housing and used strips of masking tape to hold the hull sides upright with the floor to insure they fit properly and lined up straight. The driver's side received the parking brake lever as well as the electric fuel pump switch. The case for the signal staff was added and the periscope for the side view port added with blue tack masking.

Continuing on with the fighting compartment interior, I assembled the various ammunition racks for the main gun as well as the 2 MGs. The Interior Set provides some excellent PE holders that were bent to shape with pliers and tweezers. Only the MG holders proved a tight fit, the ammo cans have small raised ridges that had to be trimmed off to allow them to slide in and out without bulging the cases in the process.

The fighting compartment roof was also cleaned up with some ejector marks needing attention. I've decided that I'm going to cut away the portion of the roof over the driver's side while leaving the turret ring area intact to support the turret. Before doing that, I will paint the underside to insure consistency in what remains. I'm going to do something similar with the engine deck hatches, so those too were prepped with their ejector marks filled and sanded and the kit-supplied PE grills installed. Last but not least, the rear hull panel had the circular cover added and the external details that mount through the hull added so that they could be painted over prior to installation.

That brought me to the turret. The first order of business was the roof and the commander's cupola. I assembled the cupola per the kit instructions but left off the view port periscopes for now since I can easily install them from the underside after the roof has been painted with the interior color.

The main gun assembly came next. The kit-supplied barrel is too long when compared to the plans in PT 13 so I replaced it with the Griffon turned aluminum barrel. The kit barrel was removed at the base and the Griffon barrel glued into position at the correct length inside the mantlet with CA gel. The recoil cylinder and gun base where then added along with the breech and block. The recoil guards and spent shell bag were installed next.

The gun was then installed to the turret front plate, following the instructions carefully to insure it could still elevate freely. I encountered a problem when trying to install the gunner's sight...it seems the Tristar instruction writers didn't realize that the design of part B26, the scope, makes it impossible to fit the locking square plate, part B27, over it as called for. The only way to install it is to remove the mount tab that's molded onto the side of the scope and is supposed to attach to the main gun so that they move coaxial, slide the plate into position, then re-glue the mount tab back onto the scope. I also drilled out the eyepiece on the scope with a pin vise and added the elevation gear and shoulder traverse to the gun to round things out. The coaxial MG will get added later on, the internal locking ring will be painted first and then installed along with the MG when the time comes.

The rest of the turret also needed some additional attention. Since there isn't any detail on the turret sides (just as on the real vehicle), I will cut away portions on both sides of the turret so you can see through from both sides as well as down into the fighting compartment. Just as with the roof, I went ahead and cleaned up their ejector marks and sanded them down in preparation for painting since I don't know exactly which areas I'm going to cut away just yet. The turret roof will remain intact since the space next to the cupola mounts an ammo bin for the main gun and I wanted to preserve that...the ammo bin is only dry-fit in this pic to give an idea of where it will sit. I also constructed the rear turret ammo bins from the Interior Set PE. These had to be modified slightly in order to fit properly by removing the rear fold-up ends on the bins. These aren't deep enough for the cans to sit correctly and were snipped off with sprue cutters to allow for proper clearance. The tool drawer chest that sits between the two ammo racks was glued into position and the commander's turret traverse and light box was added to the turret side. Getting that in the proper position is crucial as it needs to line up with the rivets on the exterior as well as clear the turret ring on the bottom so some careful fitting was called for before gluing it into position.

With all that detail work done, it was now time to paint. I applied Testors Model Master Panzer Interior Buff enamel by airbrush and used my custom mix of Red Oxide primer for the various parts I'd missed the last time around.

Now it's time to start adding these parts together and working on even more of the details!